Vegfor has the experience of building a range of models from 1 to 18 pallets .Our engineer and design team customize the vacuum cooling equipment base on clients real needs and local climate, to ensure customers get maximum cooling efficiency with the lowest cost.

| # | Model | Pallet capacity | Room Size (mm) (WxDxH) | Door Type | Supplied Power | Layout Drawing |

|---|---|---|---|---|---|---|

| 1 | VEG-1P | 1 pallet | 1400x1500x2200 | Sliding or Hydraulic | 220V~480V/50Hz(60Hz)/3P | |

| 2 | VEG-2P | 2 pallets | 1400x2600x2200 | Sliding or Hydraulic | 220V~480V/50Hz(60Hz)/3P | |

| 3 | VEG-3P | 3 pallets | 1400x3900x2200 | Sliding or Hydraulic | 220V~480V/50Hz(60Hz)/3P | |

| 4 | VEG-4P | 4 pallets | 1400x5200x2200 | Sliding or Hydraulic | 220V~480V/50Hz(60Hz)/3P | |

| 5 | VEG-6P | 6 pallets | 1400x6500x2200 | Sliding or Hydraulic | 220V~480V/50Hz(60Hz)/3P | |

| 6 | VEG-8P | 8 pallets | 2400x5300x2200 | Sliding or Hydraulic | 220V~480V/50Hz(60Hz)/3P | |

| 7 | VEG-10P | 10 pallets | 2400x6500x2200 | Sliding or Hydraulic | 220V~480V/50Hz(60Hz)/3P | |

| 8 | VEG-12P | 12 pallets | 2500x8000x2200 | Sliding or Hydraulic | 220V~480V/50Hz(60Hz)/3P | |

| *** The room size is customized base your pallet's dimension . | ||||||

Machine could be customized baas on customer installation condition.

The refrigeration system for the vacuum cooler is used to re-condense the heat laden vapor that is “boiled off” from the product being cooled. This allows the vacuum system to continue lower the atmospheric pressure inside the chamber resulting in further cooling of the fresh product. The re-condensing of the vapor also prevents the moisture from getting into the vacuum pumps.

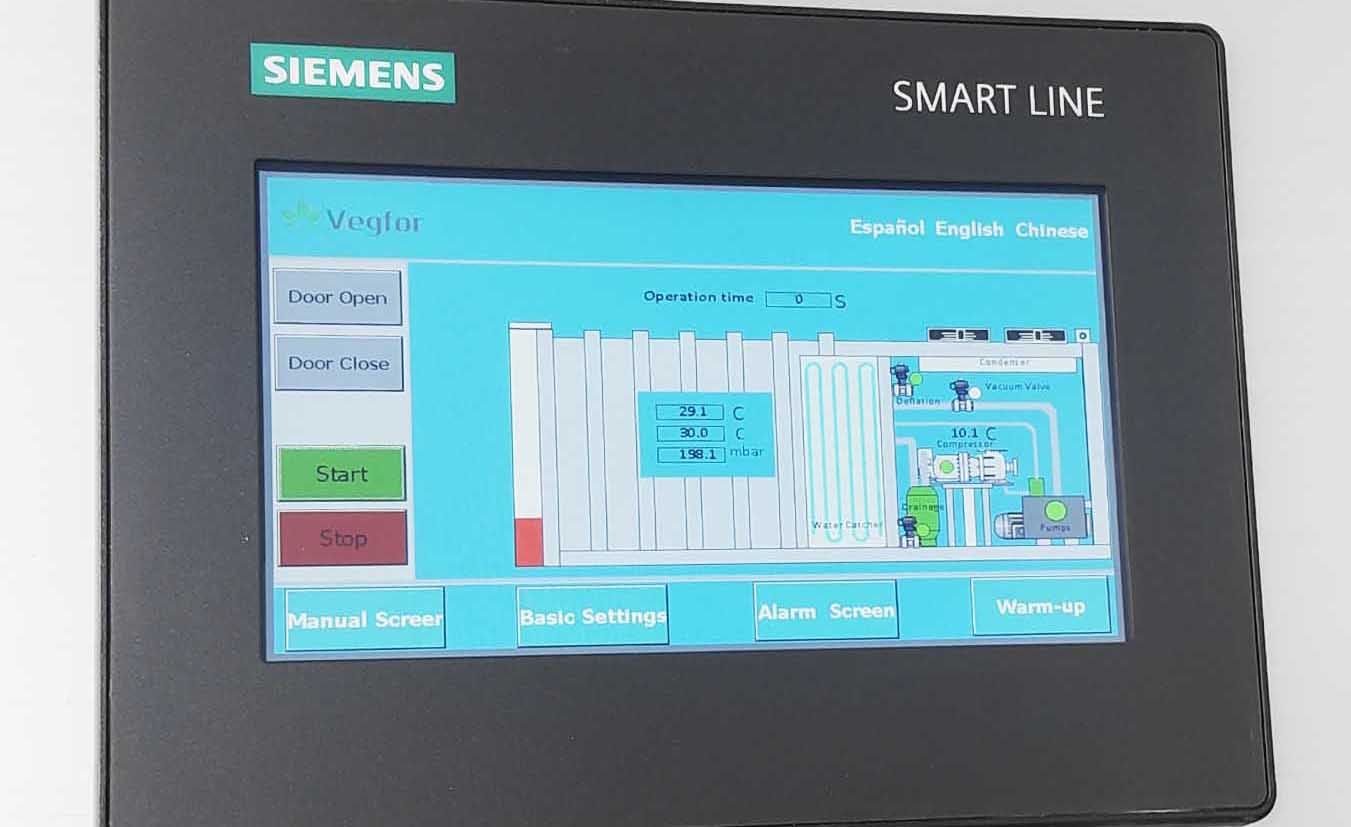

We have developed our own software (in English & local language), and combine this with the SIEMENS PLC control system and touch screen. With the software we can easily to control product temperature and other functionsFor products like broccoli and herbs, a water spray system can be installed to shorten cycle time, increase quality, and decrease water loss.